In this example we are going to use a bmp file of a fish to:

• Get the profiles of the fish to use for the embossing process

• Use the image of the fish for texture

During the layout process we are going to use the following features:

• Load Image

• Rectangle

• Change image origin

• Line join

• Ellipse

• Spline fitted

• Deform contour

• Add new layer

• Offset

• Quick trim

• Arc sketch

• Line continuous

Getting Started:

Step 1: Draw a rectangle 11” X 6”

Step 2: Draw a center line

Step 3: Draw an ellipse 9.95” X 5”

Step 4: Load Fish BMP

Step 5: Change the origin of the image to X: .95” Y: 1.25” Z: 0.0”

Click here to see video |

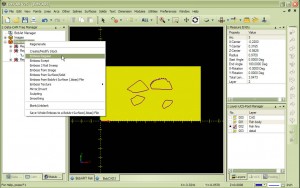

Now we are going to trace the body and fins of the fish:

Step 6: Add a new layer and make it active

Step 7: Use a fit spline to trace around the body of the fish

Step 8: Add a new layer and make it active

Step 9: Use fit spline & line continuous to trace around the fins of the fish.

Click here to see video |

Now we are going to trace the gills and eye of the fish:

Step 10: Create a new layer and make it active

Step 11: Use the fit spline to create the gills

Step 12: Use arc sketch to create the eye

Click here to see video |

Congratulations you have completed all the wire fame layout for this part!

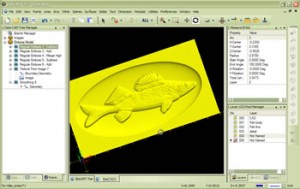

The steps we will be taking now is for the emboss model, we are going to use the wire frame we created to raise and lower areas of our emboss model

Step 1: Create/ Modify stock X:11” Y:6”

Step 2: Emboss convex ellipse subtract the ellipse

Step 3: Emboss convex ellipse add the fish body

Step 4: Emboss convex ellipse merge high the fins

Step 5: Emboss line subtract the gills

Step 6: Emboss convex art the eye

Note: If you see a red X in the BobART manager it means that you have not “regenerated” the emboss model. To do this you RT click on emboss model and LT click on regenerate.

Click here to see video |

Let’s create our emboss model:

Step 7: Regenerate your emboss model

Step 8: Texture from Image

Step 9: Create a boundary for the image texture

Step 10: Smoothing

Click here to see video |

|

|